Why Do Your Windows Fog Up in Winter? Think Again.

It might seem like a small thing – foggy windows or cold glass – but it points to a bigger question: Is glass an insulator? Many people get confused about this, especially in winter when windows feel freezing, or in summer when sunlight makes a room too hot.

Glass is all around us, in homes, offices, and cars, but it doesn’t work the way most people think. Let’s break down how glass really deals with heat and whether it helps keep you warm or cool.

Is Glass an Insulator?

Yes, glass is an insulator, but only to a certain degree. It slows down the flow of heat and doesn’t conduct electricity easily, which makes it a better insulator than metals. However, it’s not as effective as many modern insulating materials. While glass has low thermal conductivity, it still allows some heat to pass through over time.

Why is Glass a Poor Thermal Insulator?

At first glance, glass seems solid and unyielding, but on a molecular level, it behaves quite differently from traditional insulators. Unlike materials such as fibreglass or foam, which trap air within porous structures, glass is dense and lacks internal air pockets. Air, being a poor conductor of heat, contributes significantly to insulation in most materials, something glass simply doesn’t offer.

What makes glass an inadequate thermal barrier is its relatively higher thermal conductivity compared to other insulating materials. It allows heat energy to transfer more readily, especially in single-pane applications. This is why single glass windows often feel cold in winter and warm in summer—they conduct external temperatures inward.

Here’s where it gets personal: I once lived in a house with beautiful vintage windows—thin, single-pane glass from the 1950s. They had charm but no chill resistance. No matter how high we cranked the thermostat, the rooms near those windows always felt drafty. Eventually, we upgraded to double-pane windows with inert gas fills, and the difference was immediate. The new glass cut down thermal transfer, reduced condensation, and even lowered our energy bills.

Scientifically, this happens because glass molecules, though tightly bonded, still permit the vibration of atoms (heat) to move through them, just not as easily as metals, but more so than foams or rubbers. It sits in a middle ground: not a conductor, but not a great thermal insulator either.

So while glass can resist heat to a degree, it’s far from ideal on its own. That’s why modern architecture often combines it with advanced technologies like Low-E coatings, argon fills, and insulating spacers to enhance performance.

Why is Glass a Good Electric Insulator

Although glass isn’t highly effective at blocking heat, it is an excellent electrical insulator. This means it strongly resists the flow of electric current, a property that makes it essential in countless applications, from power lines to circuit boards.

The reason lies in its atomic structure. In conductive materials like metals, electrons can move freely, allowing current to flow. Glass, however, is made of tightly bonded molecules where electrons are not free to move. This results in very high electrical resistivity, often exceeding 10¹⁴ ohm-meters at room temperature. It doesn’t conduct electricity, even under high voltages, making it reliable and safe.

This property is why glass insulators are widely used in electrical transmission systems, fuse components, and high-voltage insulators. Engineers often choose borosilicate glass in particular, which offers both thermal stability and strong electrical resistance. Even as temperatures rise, its insulating capacity stays relatively strong until extreme thresholds.

I remember visiting a glass plant during a university field trip, where we watched how custom-shaped glass was made for electrical insulators. What amazed me most was how the material could endure both high voltage and outdoor conditions for decades—proof of just how non-conductive and stable glass really is.

So while glass may not insulate heat very well on its own, it’s undeniably one of the most effective and durable electrical insulators in modern use.

How Temperature Affects Glass’s Insulating Properties

The insulating properties of glass, both thermal and electrical, are significantly influenced by temperature. As conditions shift, so does glass’s ability to block heat flow or resist electrical conduction.

Electrical Insulation and Temperature

At room temperature, glass exhibits extremely high resistivity, acting as a reliable electrical insulator. However, as the temperature increases, its electrical resistance decreases, sometimes dramatically.

- At around 25°C (77°F): Glass resistivity is approximately 10¹⁴ ohm-meters, ideal for insulating electrical components.

- At 1000 K (~726°C): Resistivity drops significantly, sometimes below 10⁷ ohm-meters, meaning it begins to conduct small amounts of current.

- This decline happens because heat excites the bound electrons, making them more mobile and allowing limited current flow.

Thermal Insulation and Temperature

Unlike electrical resistance, the thermal conductivity of glass doesn’t change as drastically with temperature—but there are still key effects:

- As the temperature increases, the heat flow through the glass rises due to faster molecular vibrations.

- However, because glass is an amorphous solid (non-crystalline), its atoms are arranged irregularly, which already limits its ability to transfer heat.

- Even at high temperatures, glass still lags behind metals in heat conduction but performs worse than modern thermal insulators like foam, plastic, or mineral wool.

Practical Implications

- In electronics, overheating can cause glass insulators to fail or become semi-conductive.

- In building materials, extreme temperature swings may reduce the efficiency of single-pane glass, which is why multi-pane and Low-E treated units are preferred.

Insulating Glass Units: Improving Performance with Panes, Gas Fills, Coatings

When it comes to maximizing thermal performance, Insulating Glass Units (IGUs) are the industry standard. These advanced window systems are designed to overcome the limitations of single-pane glass by creating sealed, multi-layered barriers that drastically reduce heat transfer.

IGUs typically consist of:

- Two or more panes of glass

- A sealed air or gas-filled space between them

- An edge spacer to maintain uniform separation

- A perimeter sealant to ensure airtight performance

What makes IGUs effective isn’t just the double or triple layers—it’s the addition of inert gas fills (like argon or krypton) and Low-E (low-emissivity) coatings, which work together to minimize both conduction and radiation of heat.

Let’s compare different IGU configurations:

Why do these components matter?

- Low-E Coatings: These are microscopically thin metal layers that reflect infrared radiation (heat) while allowing visible light to pass, keeping interiors cooler in summer and warmer in winter.

- Spacers & Seals: Prevent moisture infiltration and maintain structural integrity over time.

Personal observation: When my neighbor replaced their old windows with triple-pane air-filled IGUs, not only did their home feel more comfortable year-round, but their HVAC usage dropped noticeably—confirmed by their energy bill.

So, IGUs transform ordinary glass into a high-performance insulator, balancing clarity, energy efficiency, and long-term durability. They are now a default feature in green building codes and energy-conscious architecture.

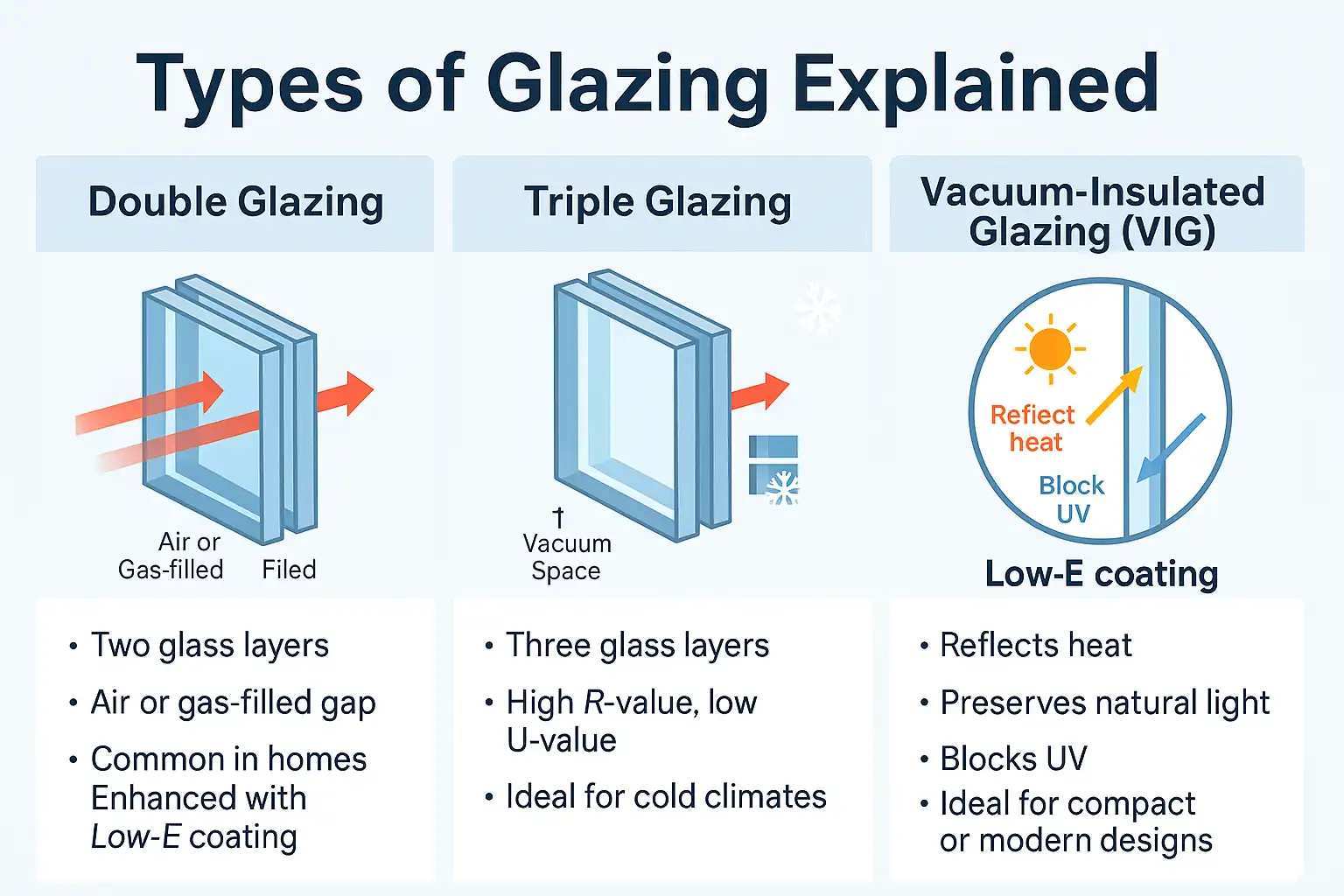

Types of Glazing: Double, Triple, and Vacuum IGUs Explained

As energy-efficient building standards continue to rise, so does the demand for high-performance glazing systems. The type of glazing used in a window can drastically affect how well it insulates, how much energy it conserves, and how comfortable it keeps interior spaces throughout the year.

Among the most common and effective options are double glazing, triple glazing, and the more advanced vacuum-insulated glazing (VIG), each engineered for specific performance needs.

Double glazing

Double glazing is perhaps the most widely used type of insulated glass unit (IGU) today. It consists of two glass panes separated by a spacer, with the cavity often filled with air. This configuration creates a thermal barrier that significantly improves insulation over traditional single-pane glass. While basic double glazing can be sufficient in moderate climates, its performance greatly improves when enhanced with features like Low-E coatings and dead air fills. These additions reduce radiant heat transfer and increase resistance to conductive heat loss, making double-glazed units a reliable choice for reducing energy consumption in homes and buildings.

Triple glazing

Triple glazing builds upon the same principle but introduces a third layer of glass and a second insulating gap. The additional layer improves thermal resistance, allowing the unit to retain heat more effectively in colder climates. With two gas-filled chambers and multiple coatings, triple-glazed windows can achieve much higher R-values and lower U-values than double-glazed windows. This makes them ideal for energy-conscious consumers in regions with harsh winters or extreme temperature swings. However, triple-glazed units are also heavier and more expensive, which can affect installation logistics and upfront costs.

Vacuum-insulated glazing (VIG)

Vacuum-insulated glazing represents a cutting-edge evolution in glass technology. Instead of using gas to fill the space between panes, VIG creates a vacuum—a space completely devoid of matter. This eliminates conductive and convective heat transfer almost entirely, resulting in insulation performance that rivals solid insulated wall panels. Despite being thinner and lighter than triple-glazed units, vacuum glazing can achieve similar or better thermal resistance. It’s especially useful in space-constrained applications or high-performance architectural designs where both aesthetics and energy efficiency are critical. However, due to the complexity of manufacturing and sealing a long-lasting vacuum, VIG remains a premium solution with a higher cost threshold.

Each of these glazing types has its place depending on the building’s needs, climate zone, and energy goals. Choosing between them involves balancing cost, performance, weight, and long-term energy savings. Understanding the science and engineering behind these glazing systems enables consumers and professionals alike to make smarter, more sustainable decisions.

Low-E coatings

Low-E coatings are microscopically thin metallic layers applied to the inner surface of one of the glass panes. These coatings reflect a large portion of infrared (heat) radiation, keeping heat inside during winter and outside during summer. Importantly, they allow visible light to pass through almost unchanged, ensuring that natural daylight is preserved without causing overheating.

- Reflects infrared heat back to its source (inside during winter, outside during summer)

- Reduces solar heat gain without darkening the glass

- Minimizes UV penetration, helping to prevent fading of fabrics, floors, and artwork

- Comes in hard coat (durable, lower performance) and soft coat (higher performance but more delicate)

Whether you’re building a new home or upgrading old windows, this dual-layer of invisible innovation delivers tangible benefits—less energy waste, greater indoor comfort, and a longer lifespan for interior materials.

Applications in Energy-Efficient Design

Residential Homes and Energy Savings

In modern residential architecture, energy efficiency is no longer a luxury—it’s an expectation. Windows are a major source of heat loss in winter and heat gain in summer, making insulated glass a crucial component of any high-performance home. By using double or triple-pane IGUs with Low-E coatings and dead air space, homeowners can reduce their HVAC usage, maintain more stable indoor temperatures, and lower utility bills. These improvements aren’t just theoretical; ENERGY STAR estimates that replacing single-pane windows with energy-efficient models can save up to $465 annually in heating and cooling costs.

Commercial Buildings and Green Certifications

In commercial construction, glass isn’t just a structural element—it’s a design feature. Office buildings, schools, and public structures often incorporate large glass façades, which can become liabilities without proper insulation. Using high-performance IGUs, especially those with vacuum glazing, allows architects to retain aesthetic appeal while meeting LEED, BREEAM, or Passive House energy standards. These applications also support climate control in large volumes, where poor insulation could lead to massive energy waste.

Retrofitting Existing Structures

Older buildings often contain single-pane glass, which lacks the insulation modern energy codes require. Retrofitting with insulated glass units is one of the most effective ways to modernize a property without major structural changes. In many cases, IGUs can be inserted into existing frames, turning a drafty room into a thermally balanced space. This is particularly effective in historical properties, where preservation requirements prevent full window replacement but still demand energy upgrades.

Solar Control and Smart Glazing

Energy-efficient glass isn’t just about keeping interiors warm; it’s also about solar control. In hot climates or sun-facing rooms, glass equipped with Low-E coatings and spectrally selective tints can minimize unwanted solar gain while preserving light. Advanced applications now include smart glass technologies, where glazing can automatically tint in response to sunlight, reducing reliance on blinds and further cutting cooling loads.

Sustainability and Long-Term Impact

High-quality insulated glass reduces a building’s carbon footprint by minimizing reliance on fossil fuels for heating and cooling. Over time, this not only contributes to lower emissions but also aligns with broader sustainability goals. Whether for a single-family home or a multi-use complex, the integration of advanced glass systems directly supports a more responsible and resilient built environment.

Comparing Glass to Other Insulation Materials

Glass vs. Fiberglass Insulation

Fiberglass is one of the most commonly used building insulators due to its low cost, ease of installation, and excellent thermal resistance. While glass in window form provides transparency and limited insulation, fiberglass batts or rolls are designed specifically to trap air and resist heat flow. Fiberglass typically has an R-value between R-2.9 and R-3.8 per inch, making it far superior to single-pane glass in terms of thermal insulation. Glass simply cannot match this performance unless it’s part of a multi-pane IGU system enhanced with coatings and gas fills.

Glass vs. Foam Board and Spray Foam

Rigid foam boards (like polyisocyanurate or extruded polystyrene) and spray foams offer even higher R-values, up to R-6.5 per inch, and are frequently used in walls, roofs, and foundations. These materials provide not only insulation but also air sealing. Compared to these, even the most advanced triple-pane or vacuum-insulated glass falls short in raw thermal resistance, though it serves different purposes where transparency and daylighting are critical.

Glass vs. Plastics and Acrylics

Some window systems use polycarbonate or acrylic sheets instead of glass. These materials are lighter, more impact-resistant, and offer slightly better insulation than single-pane glass. However, they may yellow over time and are generally less scratch-resistant. In most architectural applications, glass remains the preferred choice due to its durability, clarity, and compatibility with high-performance treatments like Low-E coatings and inert gas fills.

Glass vs. Ceramics and Insulating Tiles

In high-temperature environments like furnaces, kilns, or spacecraft, ceramic insulators are used for their extreme heat resistance. While glass can handle moderate temperatures, ceramics offer superior insulation under intense heat. However, ceramics are opaque and brittle, making them unsuitable for applications where visibility and aesthetics are essential.

Looking to Upgrade Your Glass for Better Insulation?

At Hansen Glass Inc, we specialize in custom insulated glass solutions that enhance comfort, reduce energy bills, and elevate the look of your home or business. Whether you need double-pane replacements, Low-E upgrades, or complete IGU installations, our experts are here to help.

Contact us today to discover how modern glass can transform your space, functionally and beautifully.

Final Thoughts

While glass may not be a top-tier insulator in its raw form, modern innovations have elevated it into a powerful component of energy-efficient design. Through the use of insulating glass units (IGUs), Low-E coatings, and dead air spaces, glass now offers a unique balance of thermal performance, aesthetic appeal, and natural daylighting that few other materials can match.

Whether you’re building new or upgrading old windows, understanding how glass insulation works empowers you to make smarter, more sustainable choices. It’s not just about comfort; it’s about reducing energy consumption, lowering utility costs, and contributing to a more environmentally responsible future.

So, the next time you look through a window, remember: that clear pane of glass is doing a lot more than letting the light in; it’s part of a high-performance barrier working silently to keep your space in balance.

FAQs

Is glass a good insulator of heat?

Glass is a moderate insulator of heat. On its own, it performs poorly compared to materials like foam or fiberglass. However, when used in insulating glass units (IGUs) with gas fills and Low-E coatings, it becomes an effective thermal barrier.

Does glass conduct electricity?

No, glass is a strong electrical insulator. Its tightly bound electrons prevent the flow of electric current, making it ideal for use in electrical and high-voltage applications.

Why does single-pane glass feel cold in winter?

Single-pane glass has a low R-value, meaning it allows indoor heat to escape easily. This causes the surface to feel cold and contributes to drafty interiors.

What makes Low-E glass different from regular glass?

Low-E glass has a microscopic metal coating that reflects heat while allowing visible light through. This significantly improves a window’s energy efficiency without compromising clarity.

What is the best insulating glass option for cold climates?

Triple-pane IGUs with dead air space and multiple Low-E coatings offer the best insulation for cold climates, delivering superior R-values and minimizing heat loss.