Ever had a window crack unexpectedly and wondered if there’s a cheaper, tougher alternative to traditional glass? You’re not alone. As DIY trends grow and material science evolves, plexiglass is quickly entering the spotlight.

But is it the right choice for your next window fix, or a costly mistake waiting to happen?

Can You Replace a Window with Plexiglass?

Yes, you can use plexiglass to replace a window, but it depends on the situation. While it’s lightweight, durable, and shatter-resistant, it may not offer the same clarity, insulation, or code compliance as real glass in every scenario.

Pros and Cons of Using Plexiglass Instead of Glass

Plexiglass, also known as acrylic or PMMA, is often mistaken for a low-budget alternative to real glass. But the truth is, it’s a purpose-built material with its own strengths and weaknesses.

On the plus side, plexiglass is significantly more impact-resistant than regular glass, up to 17 times stronger, in fact. It doesn’t shatter on impact, making it safer around kids or in high-traffic areas. It’s also lightweight, weighing roughly half as much as a similarly sized glass pane, which makes it easier to handle. When treated with a UV-resistant coating, it can even block up to 99% of harmful UV rays, helping to protect your interiors.

However, there are clear drawbacks. Plexiglass is not scratch-resistant, and even gentle cleaning with the wrong cloth can leave swirl marks. Over time, it may also yellow or cloud, especially if exposed to direct sunlight without proper UV protection. Another issue is thermal insulation; plexiglass does not perform as well as double-pane or low-E glass in regulating temperature, which could lead to increased energy bills in extreme climates.

I learned this the hard way when I replaced a cracked basement window with a plexiglass panel. It looked crystal-clear and installed like a dream, until the first summer. Within two months, the interior started to feel like a greenhouse. The panel had no UV coating, and the heat gain was intense. Lesson learned: always choose the right grade of plexiglass, or better yet, consult with a window specialist.

In short, plexiglass isn’t better or worse, it’s just different. Knowing where it excels (and where it doesn’t) is key to making the right decision.

Durability: Is Plexiglass Stronger Than Glass?

When it comes to durability, plexiglass often outperforms standard window glass in specific scenarios. While traditional annealed glass is brittle and prone to shattering on impact, plexiglass offers a more rugged, long-lasting alternative, especially in high-risk environments.

Here’s how they compare:

- Impact Resistance:

Plexiglass is approximately 17 times more impact-resistant than standard glass. It won’t shatter under pressure, which makes it ideal for areas prone to breakage, like garage windows, storm panels, or playroom enclosures. - Shatter Safety:

While glass breaks into dangerous shards, plexiglass cracks but typically stays in one piece. This shatter-resistant behavior reduces the risk of injury and makes cleanup easier. - Scratch Resistance:

This is where plexiglass falls short. It’s much softer than glass, meaning it scratches easily unless coated with a scratch-resistant layer. Even dust particles can cause visible swirls over time if cleaned improperly. - Weight and Flexibility:

Plexiglass is about 50% lighter than glass, making it easier to transport, cut, and install. It also has some flexibility, which adds to its shock absorption, though it can bow or warp under stress if not properly supported. - Weather and UV Exposure:

Without UV-resistant coatings, plexiglass can yellow or degrade when exposed to sunlight for extended periods. High-quality, UV-treated plexiglass can last for years without noticeable discoloration.

In summary, plexiglass excels in impact resistance and safety, but its lower scratch resistance and potential for UV degradation are important factors to consider.

Energy Efficiency and Insulation

While plexiglass shines in strength and safety, its performance in energy efficiency is a more complex story—especially when compared to modern glass window technologies like double-pane or low-E glass.

Heat Retention and U-Factor

The U-Factor measures how well a material resists heat flow. A lower U-Factor means better insulation. Standard single-pane plexiglass has a higher U-factor than double-pane glass, which means it allows more heat to pass through. This can lead to noticeable heat loss in winter and heat gain in summer, increasing your reliance on HVAC systems.

- Plexiglass (1/8″ thick) typically has a U-Factor around 1.20 to 1.40

- Double-pane glass with low-E coating can have a U-Factor as low as 0.25 to 0.35

In real-world terms, that means plexiglass is far less insulating, making it a poor choice for windows where thermal performance is a priority.

Air Sealing and Warping

Energy efficiency isn’t just about material; it’s also about installation. Plexiglass, being more flexible than glass, is prone to minor warping or bowing, especially in large panels. This can break the airtight seal around a window frame, allowing drafts to enter or escape. Even a small gap reduces insulation significantly over time.

UV and Solar Control

On the positive side, many grades of UV-resistant plexiglass block up to 99% of ultraviolet light, reducing fading of fabrics and flooring. However, UV protection is not the same as insulation—it helps protect from light damage, not heat loss.

Some specialized versions of plexiglass come with solar control features, but they are often more expensive and still underperform when compared to air-filled or low-E coated glass units. According to the U.S. Department of Energy’s Guide to Energy‑Efficient Windows, windows with lower U‑Factors (as low as 0.20–0.30) significantly reduce heat loss, leading to annual energy savings of up to $500 depending on climate.

In summary, if energy efficiency is a priority, for example, in living rooms, bedrooms, or office spaces—modern glass is the superior option. Plexiglass can work in utility areas or temporary fixes, but you may end up paying more in heating and cooling over time.

Cost Comparison: Plexiglass vs Traditional Glass

While plexiglass is often perceived as a cost-effective alternative to glass, the reality is more nuanced. Depending on the quality, finish, and performance requirements, plexiglass can actually rival or exceed the cost of traditional window glass.

Material Value Over Time

Plexiglass offers benefits such as reduced breakage and lightweight handling, but its long-term value may decline due to its tendency to scratch and discolor. On the other hand, glass, especially modern, treated options like tempered or low-E varieties, tends to hold up better over the years, offering superior clarity, insulation, and stability.

Installation Considerations

Because plexiglass is more flexible, it requires careful framing to avoid warping or air leaks. Glass, though heavier, provides a solid and rigid structure that integrates more naturally with standard window assemblies, especially in residential and commercial applications.

Cost-Efficiency Breakdown

| Feature | Plexiglass (Acrylic) | Standard Glass | Tempered/Low-E Glass |

| Material Longevity | Moderate (may yellow) | High (maintains clarity) | Very High (enhanced life) |

| Break Resistance | Very High | Low | Moderate to High |

| Maintenance Needs | Higher (scratches easily) | Low | Low |

| Energy Efficiency | Lower | Moderate | High |

| Aesthetic Durability | Prone to surface wear | Stable over time | Stable & protective |

In short, while plexiglass offers some practical advantages, glass delivers stronger long-term value, especially in settings where insulation, clarity, and code compliance are priorities.

Maintenance and Longevity

When evaluating window materials, maintenance requirements, and expected lifespan play a major role in overall value. Plexiglass and traditional glass behave very differently in terms of how they age, react to the environment, and retain their appearance over time.

Cleaning and Surface Wear

Plexiglass is particularly sensitive to abrasion. Even gentle wiping with a rough cloth can leave visible scratches. Specialized cleaners and microfiber cloths are recommended, especially if the surface lacks a scratch-resistant coating. Over time, repeated cleaning can dull its once-clear appearance.

In contrast, glass is highly scratch-resistant, tolerating regular cleaning without degrading. It maintains its optical clarity far longer and requires little more than standard glass cleaner and a soft cloth.

UV Exposure and Yellowing

Without proper treatment, plexiglass is prone to yellowing and hazing when exposed to direct sunlight. This discoloration occurs gradually and may begin to appear within a few years, especially in south-facing windows or high-UV regions. UV-resistant plexiglass extends its clarity, but this version comes at a higher cost.

Glass, especially when low-iron or coated with UV-blocking layers, resists yellowing and maintains its transparency for decades. It is inherently more stable under prolonged sun exposure.

Structural Aging

Over time, plexiglass can flex or bow, particularly in larger panels or fluctuating temperatures. This can compromise the window’s seal or aesthetics. While it doesn’t shatter like glass, its structural integrity may diminish faster in demanding environments.

Glass holds its shape rigidly, does not warp, and is less susceptible to environmental deformation. Its rigidity ensures consistent performance and a longer service life, especially in architectural installations.

In summary, plexiglass requires more careful upkeep and may show its age sooner, especially if exposed to the sun or cleaned frequently. Glass, on the other hand, offers low maintenance and long-term durability, making it a better choice for permanence and visual consistency.

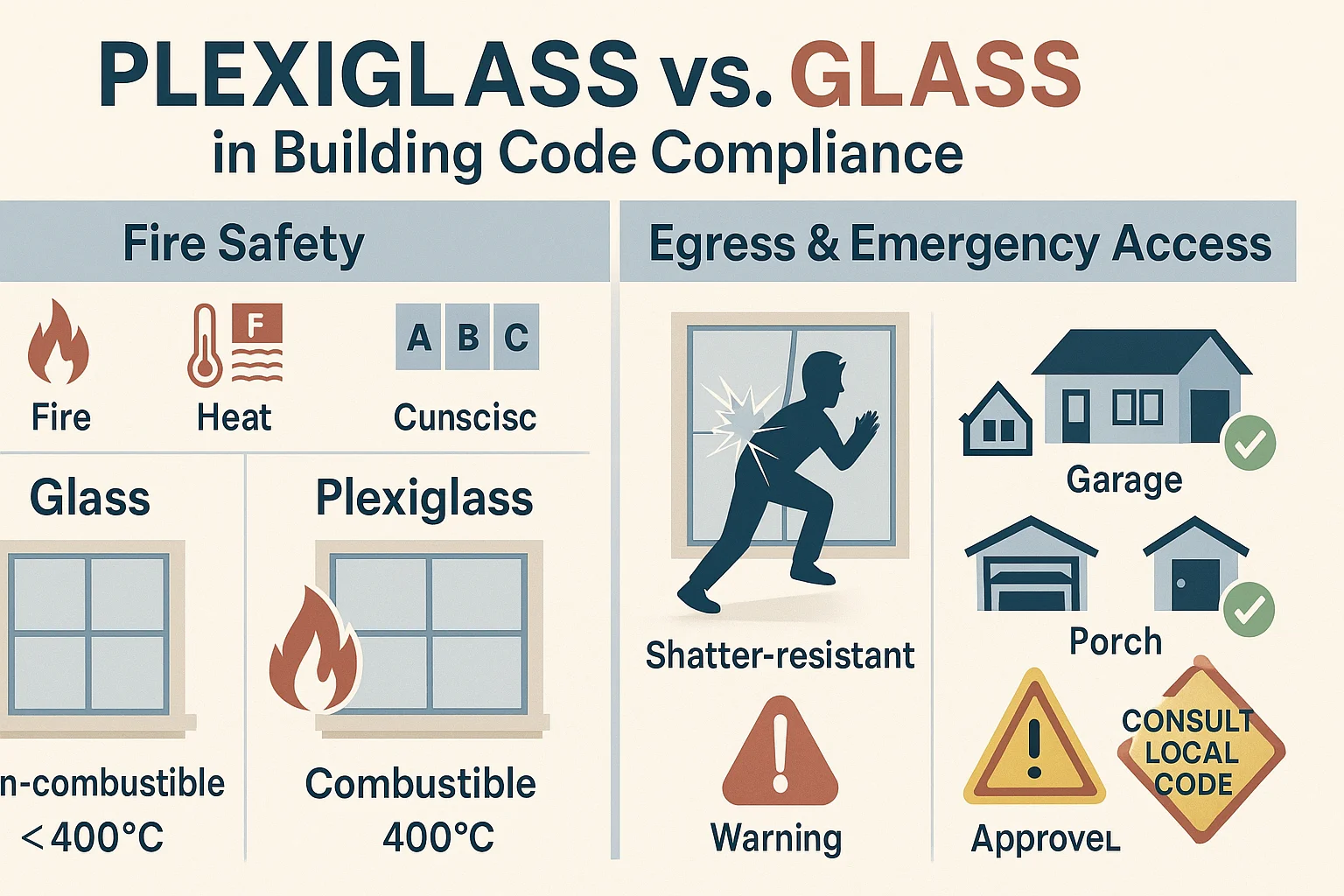

Does Plexiglass Meet Building Codes?

Before using plexiglass as a window replacement, it’s essential to consider whether it aligns with local building codes and safety regulations. While plexiglass has many practical benefits, it doesn’t automatically qualify as a code-compliant substitute for glass, especially in areas where safety, fire resistance, and emergency access are concerned.

Fire Safety and Flammability

Most jurisdictions require that window materials meet specific fire safety standards, particularly in multi-unit dwellings, exits, and near property lines. Plexiglass is combustible and can ignite at relatively low temperatures compared to glass, which is non-combustible and more heat-resistant. For this reason, plexiglass may not be suitable for applications where fire-rated materials are required.

Some specialized acrylics are treated for enhanced flame resistance, but they still typically fall short of glass’s fire performance under strict code requirements.

Egress and Emergency Access

Windows that serve as emergency exits—such as those in bedrooms or basements, must comply with egress regulations. These typically include minimum size standards and, crucially, the ability to break or remove the window quickly in an emergency. Plexiglass is shatter-resistant, which ironically can be a problem: it may not break easily enough to allow escape in a fire or emergency.

This characteristic can disqualify plexiglass in some code-governed installations where breakability is a safety feature, not a flaw.

Approved Usage Scenarios

Plexiglass is often permitted in non-habitable spaces such as garages, sheds, porch enclosures, or temporary structures. In these settings, the emphasis is less on insulation and egress, and more on basic protection and durability. Still, whether it’s allowed for permanent window replacements depends heavily on local building inspectors and code enforcement offices.

In summary, plexiglass does not universally meet building codes—especially where fire safety or emergency egress is involved. Always consult local regulations or a licensed contractor before choosing acrylic as a permanent window material.

Does Plexiglass Meet Building Codes?

Before using plexiglass as a window replacement, it’s essential to consider whether it aligns with local building codes and safety regulations. While plexiglass has many practical benefits, it doesn’t automatically qualify as a code-compliant substitute for glass, especially in areas where safety, fire resistance, and emergency access are concerned.

Fire Safety and Flammability

Most jurisdictions require that window materials meet specific fire safety standards, particularly in multi-unit dwellings, exits, and near property lines. Plexiglass is combustible and can ignite at relatively low temperatures compared to glass, which is non-combustible and more heat-resistant. For this reason, plexiglass may not be suitable for applications where fire-rated materials are required.

Some specialized acrylics are treated for enhanced flame resistance, but they still typically fall short of glass’s fire performance under strict code requirements.

Egress and Emergency Access

Windows that serve as emergency exits, such as those in bedrooms or basements, must comply with egress regulations. These typically include minimum size standards and, crucially, the ability to break or remove the window quickly in an emergency. Plexiglass is shatter-resistant, which ironically can be a problem: it may not break easily enough to allow escape in a fire or emergency.

This characteristic can disqualify plexiglass in some code-governed installations where breakability is a safety feature, not a flaw.

Approved Usage Scenarios

Plexiglass is often permitted in non-habitable spaces such as garages, sheds, porch enclosures, or temporary structures. In these settings, the emphasis is less on insulation and egress, and more on basic protection and durability. Still, whether it’s allowed for permanent window replacements depends heavily on local building inspectors and code enforcement offices.

In summary, plexiglass does not universally meet building codes—especially where fire safety or emergency egress is involved. Always consult local regulations or a licensed contractor before choosing acrylic as a permanent window material.

Plexiglass vs Polycarbonate: What’s the Difference?

Though often confused, plexiglass (acrylic or PMMA) and polycarbonate are two very different plastics, each with distinct characteristics that influence their suitability for window replacement.

Material Composition and Strength

- Plexiglass (Acrylic) is made from polymethyl methacrylate, offering excellent clarity, good UV resistance (if treated), and a rigid structure. It’s significantly more impact-resistant than glass, but not unbreakable.

- Polycarbonate, on the other hand, is a much tougher thermoplastic. It boasts up to 250 times the impact resistance of glass, far beyond even plexiglass. This makes it the preferred material in high-security applications such as riot shields, machine guards, and some bullet-resistant windows.

Clarity and Aesthetics

Plexiglass generally offers better optical clarity than polycarbonate. It maintains its transparency over time, especially with UV-resistant coatings. Polycarbonate can sometimes have a slight haze or tint, and while clear grades exist, they’re not always as visually pure as acrylic.

Durability and Wear Resistance

- Polycarbonate is virtually unbreakable, but it scratches more easily than plexiglass unless treated with a hard coating. It’s also more prone to yellowing over long periods if not UV-stabilized.

- Plexiglass is naturally more scratch-resistant than untreated polycarbonate but still softer than glass. High-end plexiglass can be treated for even better surface durability.

Flexibility and Handling

Polycarbonate is much more flexible than plexiglass. While this makes it less likely to crack under pressure, it also requires more support during installation to prevent bowing. Plexiglass is stiffer, which provides more structure but also makes it more brittle under stress.

Cost and Availability

Polycarbonate is generally more expensive than plexiglass, especially in grades designed for outdoor or architectural use. Due to its strength, it’s often overkill for standard window replacements unless vandal resistance or security is a top concern.

Bottom line: Choose plexiglass for clear visibility, basic impact resistance, and affordability. Choose polycarbonate when maximum strength and safety are the priority, even if it means sacrificing some optical clarity and paying a premium.

Need Professional Window Replacement Advice?

If you’re unsure whether plexiglass or traditional glass is right for your next project, don’t guess; ask a pro. The experts at Hansen Glass specialize in custom glass solutions, offering decades of experience in helping homeowners and businesses make the right choice.

Serving the greater Parker, Colorado area with trusted craftsmanship and local expertise.

Contact Hansenglassinc to schedule a consultation today.

Final Thoughts

Plexiglass can be a smart choice for specific window applications, but it isn’t a one-size-fits-all solution.

If you need something shatter-resistant, lightweight, and simple to install in areas like garages, sheds, or utility spaces, plexiglass can perform well. Its impact resistance and safety benefits make it a practical material in environments where breakage is a concern.

However, for living spaces, long-term installations, or windows that must meet strict building codes, traditional glass, especially modern variants like tempered or low-E glass, remains the gold standard. Glass provides better thermal insulation, optical clarity, and regulatory compliance, often making it the more cost-effective option over time.

In short: use plexiglass when safety, strength, or budget are top concerns, but stick with glass when clarity, efficiency, and compliance matter most.

FAQs: Replacing Windows with Plexiglass

1. Is plexiglass safe to use as a window material?

Yes, plexiglass is safe for many applications. It’s shatter-resistant and lightweight, making it a safer alternative to traditional glass in some scenarios. However, it may not be suitable for areas requiring fire-rated materials or emergency egress.

2. Will plexiglass yellow or become cloudy over time?

Untreated plexiglass can yellow or haze when exposed to UV light. UV-resistant grades help maintain clarity for longer, but visual degradation is still possible over time.

3. Is plexiglass more durable than glass?

In terms of impact resistance, yes, plexiglass is significantly tougher than standard glass. However, it is more prone to scratching and warping, which can affect longevity.

4. Can plexiglass be used in double-pane windows?

Typically, no. Most double-pane (insulated) glass units are factory-sealed using glass. Plexiglass isn’t commonly used in IGUs due to its thermal expansion and potential for seal failure.

5. Does plexiglass help with insulation?

Plexiglass insulates better than single-pane glass but much less effectively than double-pane or low-E glass. It’s not ideal for thermal performance in climate-controlled spaces.